Food Production Facility, Unloading Containment System

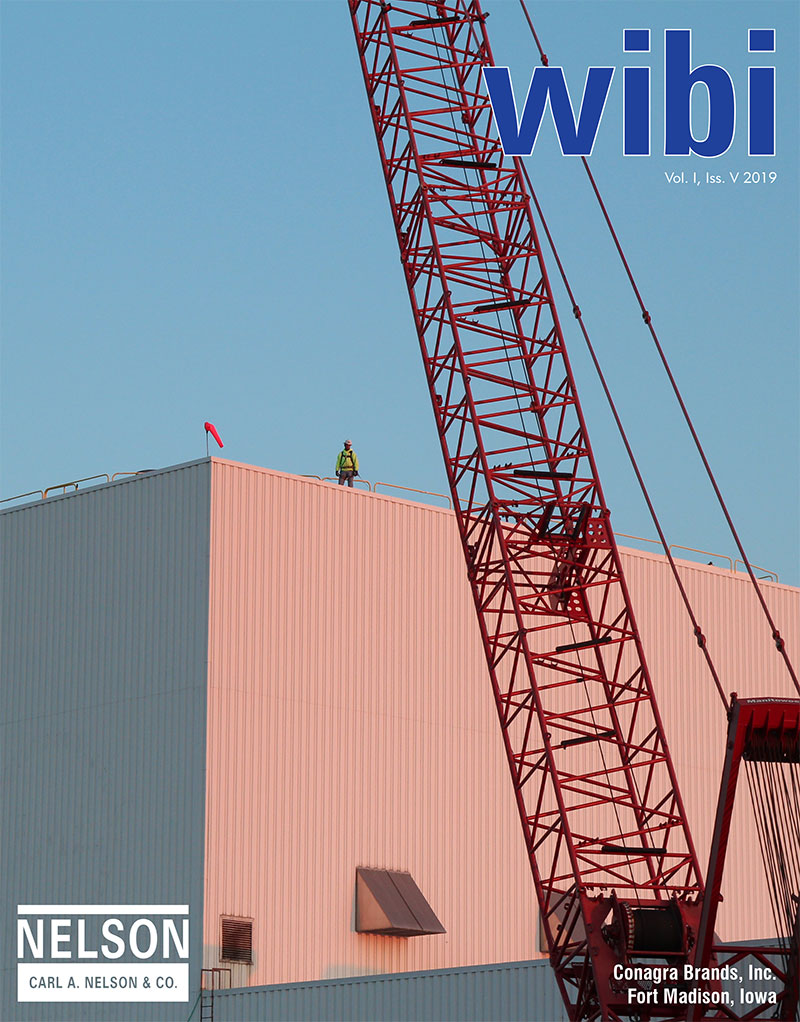

Pinnacle Foods/Conagra Brands, Fort Madison, Iowa

Project Overview

| Owner | Pinnacle Foods Group, LLC |

|---|---|

| Location | Fort Madison, IA |

| Delivery Method | Design-Build |

| Description | New Construction |

| Gross Floor Area | 16,400 SF |

The Flex Can Project for Pinnacle Foods/Conagra Brands consists of 16,400 SF of food production facility and a new product unloading containment system. The plant in Ft. Madison is part of a consolidation of production facilities by Pinnacle Foods LLC. This addition replaced the production facility in Tacoma, Washington. The company's total investment was approximately $20,000,000.

The building expansion was attached to the existing production facility between an existing ammonia compressor building and boiler house. The building site was loaded with buried underground utilities; high voltage electric feeds, steam and condensate lines, process waste and sanitary sewer lines, C02 lines, fire and process water lines and brine lines. The building also had to be built under the existing ammonia piping bridge that could not be moved. The Flex Can addition project is constructed with reinforced concrete spread footings and reinforced concrete wall. The exterior walls are load bearing insulated precast panels with precast double tee roof structure and a TPO roof system. The floor system was a double abrasive acid brick floor utilizing epoxy grout for the setting bed and joints. A reinforced concrete pit for installation of vertical retorts is installed.

The project was awarded to Carl A. Nelson & Company in December and had to be designed, built, and completed in seven months to allow the Owner to install the process equipment to facilitate a September production date. Carl A. Nelson & Company was substantially complete with the project in six months.