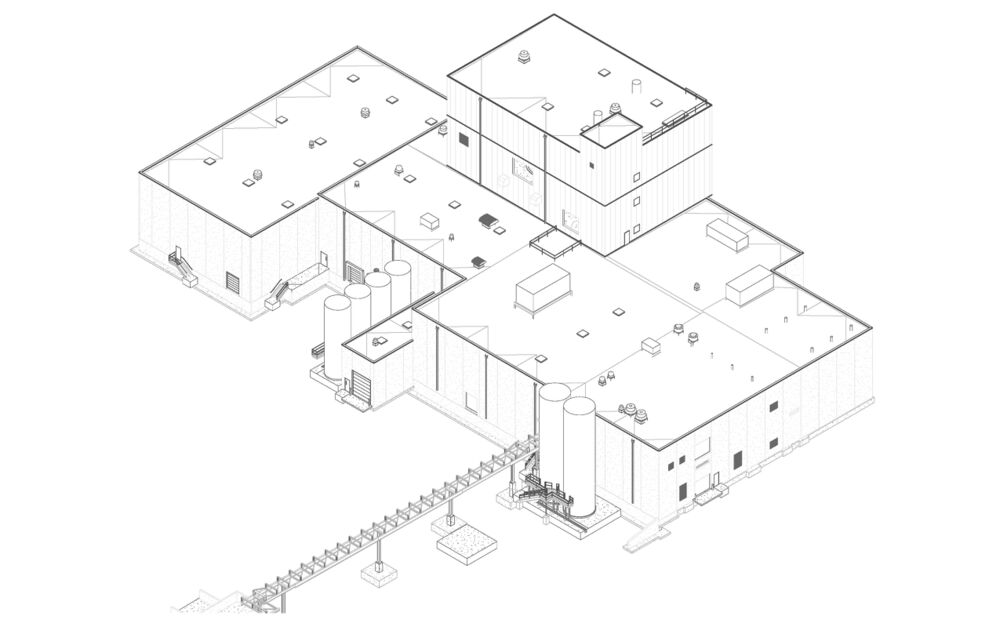

Food Ingredient Production Facility

Confidential Client, Cedar Rapids, Iowa

Project Overview

| Owner | Confidential |

|---|---|

| Location | Cedar Rapids, Iowa |

| Delivery Method | Design-Build |

| Description | New Construction |

| Gross Floor Area | 100,000 SF |

This Design-Build project is a 100,000 SF food-grade yeast extract manufacturing facility located in Cedar Rapids, Iowa. Besides production,the facility includes administrative offices, warehouse space, shipping and receiving, and maintenance and parts storage space. Due to the volume of hazardous materials, portions of the building were classified as H-4 High Hazard Group Occupancy.

Carl A. Nelson & Company led the design-build team for this project. Our scope included design and construction of the facility except for electrical design, and process equipment selection and procurement. Carl A. Nelson & Company managed the coordination between design disciplines, cost control, schedule management, site supervision, site safety management, site layout, substructure and superstructure concrete work, concrete flatwork, steel and precast concrete erection, metal panel erection, rough and finish carpentry, metal studs, and drywall. Carl A. Nelson & Company’s craftsman self-performed 54% of the work on this project.

All the architectural and structural drawings were produced in a Revit Building Information Model (BIM). The Revit model included the building mechanical drawings, produced in 3D AutoCAD, and the process piping layout completed by the owner. Interference checking was completed in the model for coordination purposes eliminating costly delays and unnecessary changes during construction.